SimSpray for Industrial Coatings

Improve Access to Training

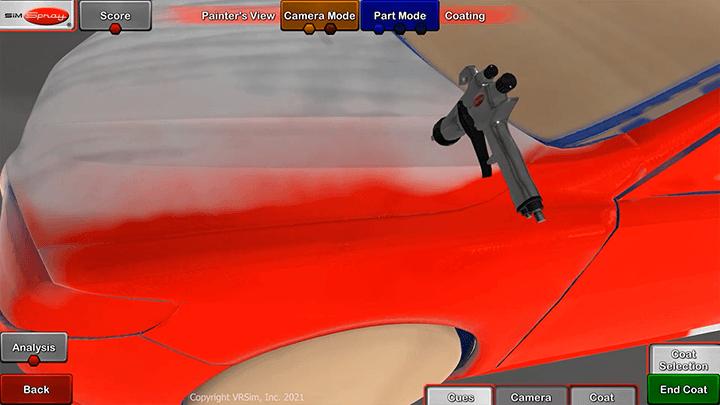

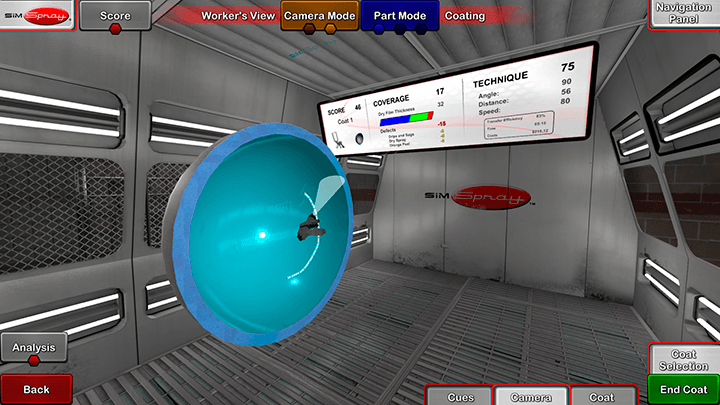

Hands-On Experience at the Push of a Button

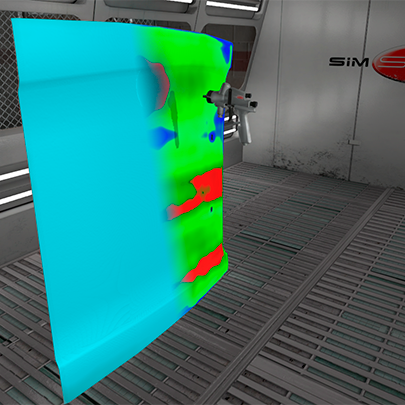

SimSpray removes barriers from the learning experience. Get more practice time, better feedback with real-time visuals of the coating thickness, and save on prep time and material costs. Complete and repeat coating projects with ease to help trainees learn and master skills faster.

Research-Backed and Adopted Worldwide

High-quality training features to support faster, safer, better training. These virtual reality training tools allow you to teach coating skills up to 5x faster and reduce material costs by up to 50%. Not convinced? Check out our resources and customer feedback to see why SimSpray works.

VR Study Excerpt - Studying the impact of VR on skills training

Paint Infographic - Exploring the benefits of VR painter training

Customer Testimonials - Outcomes and impact from our customers